|

Basic research nourishes the growth of photonic

metamaterials and plasmonics, while the desires of the consumer

result in laser TV and higher-capacity optical disks. At the center

of it all is the photonics industry, making things

happen.

Going to a photonics conference to gawk at the technology can be

a rewarding experience. There one can see, in the technical

sessions, some rather stunning achievements. While no physical laws

are violated as leading-edge researchers discover new ways to

exploit light in science and engineering, they certainly seem to

come close to bending the rules.

Spending time on the exhibit floor can be just as satisfying-that

is where one finds the practical results of all this research. In

fact, the interaction between research and commercialization is not

a one-way street. Anyone who spends time in the technical sessions

will discover presentations given by researchers from photonics

companies worldwide, both large and small. This technology feeds

back to the universities, perhaps through a post-session

conversation between interested parties or a later formal

collaboration. In addition, the latest and greatest optical

instruments seen on the exhibit floor become the building blocks for

future research setups.

Sometimes, the results of this research are not found on the

exhibit floor of a photonics show. Instead, they find their way into

your automobile (advanced lighting, fiber-optic communications),

your computer (optical data storage and, someday soon, optical data

interconnects), or your pocket (digital-camera sensors, novel lenses

for cell phones and cameras). In this way the photonics industry,

already many billions of dollars in size, is edging closer to

becoming a behemoth the likes of the electronics industry.

Bringing practical optical interconnects for computers

(board-to-board, chip-to-chip, and perhaps intrachip) and other

integrated photonics a step closer to reality, a group of

researchers at Intel and the University of California-Santa Barbara

(both of Santa Barbara, CA) fabricated electrically injected indium

phosphide (InP) 1550-nm-emitting diode lasers on silicon, while

researchers at Ghent University (Ghent, Belgium) and the Technical

University Eindhoven (Eindhoven, The Netherlands) independently

created the same sort of device, but used a different approach (see

“Two groups create electrically injected hybrid lasers on silicon,”

www.laserfocusworld.com/articles/274700).

In the Intel version, an InP light source is bonded to a

silicon-on-insulator (SOI) waveguide with a mere-nanometers-thick

oxide layer serving as the glue via a high-temperature bonding

process; the SOI becomes the laser cavity (SOI is an easy-to-create,

optically transparent layer well-suited to integrated photonics). In

contrast, the Belgian/Dutch device uses benzocyclobutene, a polymer,

as the adhesive, with a complete InP laser coupling its light into a

layer of SOI via a polymer inverted-taper waveguide (see Fig. 1).

FIGURE 1. An adiabatic inverted-taper structure

couples light from an InP laser diode (not shown) from a

polyimide waveguide layer into an SOI waveguide (green) on

silicon. |

The European group also created similar devices with slightly

different geometry that served as photodetectors. Shortening the InP

section from the laser’s 500 µm to 50 µm for the detector, the

researchers measured a responsivity of 0.23 A/W at 1555 nm.1

In another yield from its continuing push into silicon photonics,

Intel has created a high-power monolithic integrated Raman

ring-cavity silicon laser that emits up to 30 mW at a 686 nm

wavelength.2 Because the

laser’s structure can be fabricated entirely by processes akin to

conventional computer-chip fabrication (as opposed to the InP hybrid

lasers, which must be manipulated into place and then bonded onto

SOI), this sort of laser is potentially very low in cost and can be

highly integrated with other silicon photonics. The laser is,

however, optically pumped (at 1550 nm). Cascading these lasers,

each of which lengthens the wavelength of its pump light, can

potentially result in a room-temperature mid-IR semiconductor laser.

Research into metamaterials proceeds apace (see “Meta 2006

highlights random, periodic optical metamaterials,” www.laserfocusworld.com/articles/266371), with one

result in particular capturing the attention of the popular press:

cloaking for invisibility. In the scheme, developed by John Pendry

of Imperial College (London, England) and others, a metamaterial

structure surrounds an object, redirecting any light striking the

metamaterial so that it swerves around the object, then exits the

cloak on the other side along its original path, making the object

appear not to exist.3

One problem is what the popular press has done with this

idea-like describing fanciful devices such as mantles that hide cars

or people. In reality, scientists take pains to make sure that a

metamaterial is mechanically stable to dimensions much smaller than

the relevant wavelength of electromagnetic radiation; this

requirement, along with metamaterials’ significant attenuation of

light, means that optical-metamaterial-based invisibility cloaks

millions of wavelengths in extent (in other words, people-hiders)

are impractical.

A cloak of invisibility has, however, been demonstrated at

microwave frequencies.4

David Schurig and his colleagues at Duke University (Durham, NC),

Imperial College (London, England), and SensorMetrix (San Diego, CA)

rely on a “transformation-based” cloak design (one in which

Maxwell’s equations undergo coordinate transformations) to channel

8.5 GHz (3.6 mm) microwaves around a 50‑mm-diameter copper

cylinder. The cylindrical metamaterial structure approximates a 2-D

(planar) cloaking device, rather than a full 3-D device; has a

lattice spacing of about 3.3 mm, and results in partial invisibility

(see Fig. 2). The results are of interest for both civilian

(cell-phone transmission) and military stealth use.

FIGURE 2. A simulation of a microwave cloak with

ideal material properties shows a high degree of cloaking (a),

while a simulation based on material properties of the actual

structure provides less cloaking (b). Experimental measurement

of microwave propagation around a bare copper cylinder reveals

a shadow (c); measurement of the cloaked cylinder shows that

the shadow is reduced, although not eliminated (d).

|

While they once held the position of most exotic laboratory

optical material (a spot now occupied by metamaterials, or perhaps

surface-plasmon structures), photonic crystals (PCs) have landed

solidly in the real world. For example, waveguides within 2‑D PCs

can be engineered to slow light down drastically, potentially

leading to very compact optical delays and buffers for integrated

optics. The bandwidth of such devices, however, is quite narrow.

Toshihiko Baba and his group at Yokohama National University

(Yokohama, Japan) are refining a variety of techniques to widen the

bandwidth (zero-dispersion region) of slow-light photonic-crystal

waveguides. In one device, two PC waveguides, one with no holes and

the other with small holes offset from the lattice by half a period,

are fabricated next to each other. The waveguides have dispersions

opposite to one another; as light propagating down one waveguide

couples into the other, dispersion is canceled over a 9 nm spectral

region and light is slowed to c/50. Baba’s group has also slowed

light to from c/30 to c/40 with a 35 nm bandwidth in a

chirped-structure PC (see Fig. 3); lower speeds and wider bandwidths

will be reached by combining one of these approaches with dynamic

tuning (trapping light without compressing the pulses).

FIGURE 3. Two adjacent photonic-crystal waveguides,

one with no holes (a) and the other with offset holes reduced

in size (b), serve as a coupler that slows light in a

dispersion-free manner. A chirped structure (hole sizes

varying along the length) further refines its

properties. |

Many, if not most, typical 2-D and 3-D PCs have only partial

bandgaps; achieving a complete bandgap is only possible if the

difference in refractive index between the components is high

enough. With a refractive index of 2.2 and a large transmission

window of 0.45 to 5 mm, lithium niobate (LiNbO3) would seem to be the ideal

material for PCs; in addition, its large nonlinear coefficients

would allow harmonic generation and other nonlinear effects.

Guangyong Zhou and Min Gu of the Centre for Micro-Photonics and

CUDOS (an Australia Research Council Centre of Excellence for

ultrahigh-bandwidth devices for optical systems) at Swinburne

University of Technology (Hawthorn, Australia) are creating 3-D PCs

from LiNbO3 using

femtosecond-laser-induced microexplosions to “write” the PC

structure. One problem is the strong spherical aberration induced by

the large index mismatch between the LiNbO3 and its surrounding medium,

which deforms and broadens the focused spot. The researchers

sidestep this problem by writing just above the ablation threshold.

They have fabricated a 16-layer face-centered-cubic PC that

suppresses transmission by up to 30% in its bandgap (see Fig. 4).

Further research includes the use of a liquid-crystal phase

modulator to sharpen the fabrication beam, which will produce PCs

with greater transmission suppression; and studying nonlinear

optical effects in the structure.

FIGURE 4. A face-centered-cubic (FCC) photonic

crystal is fabricated in lithium niobate with ultrafast-laser

pulses; the pulses cause microexplosions that create voids in

the material. |

Abandoning the concept of crystallinity in photonic

microstructures can have its advantages, as George Barbastathis of

the Massachusetts Institute of Technology (Cambridge, MA) and his

group demonstrates. They have developed “photonic noncrystals”

consisting of, in one theoretical example, many parallel linear

arrays of short vertical rods; the arrays, which have a spacing that

varies as a function of distance from the central axis, form a

planar gradient-index (GRIN) lens (see Fig. 5). Because they are

photolithographically fabricated, the refractive-index profiles of

these GRIN lenses can be very precisely tailored through the spacing

and diameter of the rods; the standard parabolic profile can be

modified to allow tight focusing in very short lengths.

FIGURE 5a. A 2-D “photonic-noncrystal” lens consists

of high-index rods that vary in density from the optical axis

to create an approximately parabolic effective-index

profile. |

Figure 5b. Optimizing the profile by adding

nonparabolic terms allows the lens to be made very short,

while at the same time reducing the size of the focused spot

(bottom). |

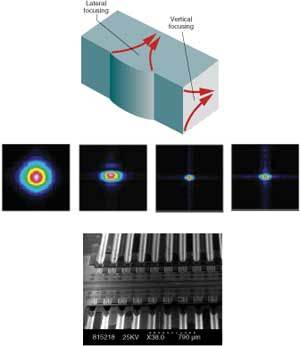

Moving into the domain of nanostructures, researchers at

Northwestern University and OptoNet (both of Evanston, IL) have

developed a 20-µm-long polarization-independent “super GRIN” lens

that can be fabricated on silicon using CMOS-compatible processes.

The lens focuses light (at 1550 nm) in two dimensions: one by a

one-dimensional curve on its entrance face, and the other by

nanolayers of two different optical materials (titanium dioxide and

silicon dioxide) that vary from 25 to 50 nm in thickness,

providing a parabolic index profile. The motivation is to couple

light from a standard single-mode optical fiber directly into

nanosize waveguides such as photonic wells and wires with height and

width on the order of a few hundred nanometers; simulations show a

95.6% coupling efficiency into a 500 nm waveguide.

A fabricated super-GRIN lens has excellent focusing qualities

(see Fig. 6). The lens has a numerical aperture (NA) of 1.5,

although NAs up to 3 are possible in the future with the use of

other material combinations (for example, silicon dioxide and

silicon), says Seng-Tiang Ho, one of the Northwestern researchers.

V-groove super-GRIN arrays have been created, demonstrating their

potential for integration into multifunctional photonic circuits.

Click here to enlarge

image

FIGURE 6.

Fabrication of a nanolayered GRIN lens (top) is CMOS

compatible. Mode and spot sizes (middle, from left to right)

are compared for single-mode fiber (8 × 8 µm); wedge fiber (3

× 8 µm); a super-GRIN lens (0.9 × 2 µm); and a laser diode (1

× 3.5 µm). Super-GRIN lenses serve to couple light from fibers

in V-groove arrays into planar nanowaveguides

bottom). |

Optical sensing of trace substances is essential in the areas of

security, industrial-process monitoring, science, and others.

Although such techniques often rely on spectroscopy, other

approaches abound. For example, a toroidal optical microcavity

developed by Andrea Armani and Kerry Vahala of the California

Institute of Technology (Pasadena, CA) sensitively measures the

proportion of heavy water (water in which the hydrogen is replaced

by deuterium) in a sample of water.5 The ring is immersed in the

water sample, and light at a 1300 nm wavelength is coupled into the

ring via a tapered optical fiber; the surrounding water slightly

absorbs the evanescent light waves at the surface of the ring,

affecting the cavity’s Q (quality) factor. The absorption

coefficient at 1300 nm for heavy water (0.208 cm‑1) results in a Q of

107; ordinary water

(1.374 cm-1)

produces a Q of 106.

“The concentration of heavy water that occurs in nature is

approximately one in 6400,” says Armani. “Using this technique, it

is possible to detect one heavy-water molecule in 10,000. This is

the first system that is able to cross the threshold and detect

real-time fluctuations in the naturally occurring population.”

Armani notes that the most obvious application is in the development

of nuclear weapons, because heavy water is typically found wherever

someone is trying to control a nuclear chain reaction. However,

there are additional applications in water-supply and environmental

monitoring.

As for spectroscopic detection of common organic substances

(drugs, biological tissue, and industrial chemicals), the mid-IR is

all-important, because it encompasses the vibrational modes of many

molecules. Harnessing the richness of this spectral region has not

been easy, however, due to the lack of an easy-to-use broadly

tunable light source. A quantum-cascade laser developed by Daylight

Solutions (Poway, CA) and integrated into a package a few

centimeters in size has a ±5% tuning range and a center wavelength

that can range from 4.5 to 11.0 µm (see “Broadly tunable QC laser

enters the market,” www.laserfocusworld.com/articles/252457; also,

“Tunable QC laser opens up mid-IR sensing applications,” www.laserfocusworld.com/articles/259939). Combining

this laser with a room-temperature mid-IR detector will result in

small, rugged optical sensors to detect explosives, pollutants, and

even breath-borne substances that indicate disease.

Photonic technology contributes to efficient energy use in a

variety of ways: non-fossil-fuel energy production (photovoltaics);

energy conservation (high-efficiency lighting); and new

oil-exploration techniques (see “Photonics and the energy crisis,”

http://www.laserfocusworld.com/articles/272166)

In photovoltaics, cadmium selenide (CdSe) quantum dots assembled

in titanium dioxide films form solar cells that are tunable in

spectral response (by varying the size of the CdSe dots) and, due to

the fact that high-energy photons can produce multiple charge

carriers in quantum dots, have the potential for a photon-conversion

efficiency of greater than 100% (see “Quantum dots promise

next-generation solar cells,” www.laserfocusworld.com/articles/252486). And, in

the area of organic photovoltaics, which typically are inefficient

and degrade easily, a solar cell based on a new ionic liquid has a

7% efficiency that does not degrade even after 2000 hours of extreme

environmental testing (see “Ionic-liquid solar cell boasts 7%

efficiency,” www.laserfocusworld.com/articles/266359).

One way to boost the efficiency of an inorganic LED is to find a

better way to extract light from the LED chip-which, with its very

high refractive index, tends to hold onto much of its light output

as a result of total internal reflection (TIR) within the chip.

Microstructured, nanostructured, pyramidal, lensed, and other

geometries have been devised for this purpose; now, Wanli Chi and

Nicholas George of the University of Rochester (Rochester, NY) have

created a compact and efficient approach in which an LED is embedded

in a transparent sphere with either a planar reflecting cut or a

small scattering section (see Fig. 7).6 While most rays from an LED

embedded in a dielectric sphere would never escape due to TIR, the

scatterer or planar mirror serve to redirect the rays out, with a

calculated efficiency of 90% or greater for a refractive index of

1.5. For a 300 µm LED die that emits 40% from its front surface and

15% from each of its four sides, the far-field output approaches a

flat-top distribution with a ±10° angular range.

FIGURE 7. Light is extracted at 91% efficiency from

an LED embedded in a transparent sphere that incorporates

either a scatterer (top) or a planar cut serving as a mirror

(bottom). The mirror relies on TIR and does not need a

reflective coating. |

Vertical-cavity lasers developed by Novalux (Sunnyvale, CA) can

be integrated into a large-screen projection-TV display that

consumes a fraction of the electrical power used by a plasma TV (see

“Photonics and the energy crisis,” www.laserfocusworld.com/articles/272166); depending

on electrical rates, the laser TV would pay for itself through

energy savings alone in anywhere from three to eight years. It

appears that this technology is going commercial; Novalux is working

with Arasor (Mountain View, CA), which provides periodically poled

lithium niobate crystals for the TV, in pushing the technology to

the market; plans are for consumer-electronics manufacturers

Mitsubishi and Samsung to launch projection TVs based on Novalux

lasers by December 2007.

The most versatile and productive way to image smaller features

(in the sense of seeing, as in a microscope, rather than printing,

as in photolithography) is to move to shorter wavelengths. While

features as small as 15 nm have been imaged by optical systems that

rely on building-size synchrotrons as extreme-ultraviolet (EUV)

light sources, few researchers have synchrotrons in their labs.

Researchers at Colorado State University (Fort Collins, CO) and

Lawrence Berkeley National Laboratory (Berkeley, CA) have imaged 38

nm features with a Fresnel-zone-plate-based optical system combined

with a tabletop EUV laser. (Also, see “Coherent light sources reach

the extreme ultraviolet,’’ p. 69.)

Joule-level pulses at 5 Hz from a Ti:sapphire laser are focused

onto a solid target to produce a plasma in a nickel-like state,

producing 13 nm light. A 5-mm-diameter condensor zone plate focuses

light onto the object; a 0.1-mm-diameter zone plate with minimum

zone size of 50 nm images onto a back-thinned, EUV-sensitive CCD

with a 2048 × 2048-pixel array. Elbows, dense lines, and complex

test patterns are imaged (see Fig. 8).

FIGURE 8. Lines and spaces 50 and 38 nm wide are

imaged with a tabletop optical system based on a 13 nm

wavelength. The high modulation of 70% for the 38 nm lines

indicates that even smaller features can be

resolved. |

The industrial-imaging arena has seen much innovation this year.

Princeton Lightwave (Cranbury, NJ) has developed a dual-band camera

that optically combines two very different optical sensors (see

“Infrared cameras vie for multispectral applications,” www.vision-systems.com/articles/274263). One sensor,

for the visible (400 to 900 nm), is a 2048-element linear CCD array;

the other, for IR (1000 to 1700 nm), is a 512-element linear indium

gallium arsenide photodiode array. The alignment places each IR

pixel at every fourth visible pixel for simultaneous aligned

imaging.

In an interesting trend, manufacturers of “smart cameras” (which

contain embedded processors and software) are loading up lots of

third-party imaging software into their cameras, offering systems

integrators multiple software choices when using their cameras (see

“Smart cameras look for smarter uses,” www.vision-systems.com/articles/272328). For

example, a camera by Sony (Tokyo, Japan) can run various x86-based

operating systems, allowing the use of either costly but mature

imaging software on Windows XP, or free applications being developed

for Linux.

The fabrication of aspheric optics heavily relies on

interferometric testing; for surface departures from sphericity of

more than a few waves, null optics are usually required (null optics

change the interferometer’s spherical wavefront to an aspherical one

that matches the desired surface figure of the optic under test).

But null optics themselves are difficult to use. Engineers at QED

Technologies (Rochester, NY) are extending the capabilities of the

company’s subaperture-stitching interferometer (SSI) to handle

optics with higher asphericity, simplifying the measurement

process.7

The SSI combines a standard interferometer by Zygo (Middlefield,

CT) with control software and additional hardware by QED to allow

subaperture measurements to be combined into a full-aperture

interferogram. When used on an asphere, the SSI measures small,

almost spherical segments of the optic and combines them. A mirror

fabricated by SSG-Tinsley (Wilmington, MA) for NASA was tested; the

100-mm-diameter ellipsoid had a base radius of -226 mm and an

aspheric departure of about 12 µm. Measurements with the SSI

agreed well with a separate measurement using null optics (see Fig.

9).

FIGURE 9. A conventional interferometric measurement

(left) of an aspheric mirror uses a retrosphere as the null

optics; a subaperture-stitching measurement of the same mirror

(right) requires no null optics. Both measurements show

similar results. |

The newly commercially introduced blue-light-based

optical-recording media, Blu-ray and HD-DVD disks, can hold anywhere

from 15 to 50 GByte of data; capacities substantially higher than

this will require a change in technology. Researchers at the

University of Miami (Coral Gables, FL) and New Span Opto-Technology

(Miami, FL) may have developed this technology-a holographic

optical-storage technique that retains the conventional bit-oriented

approach and is thus compatible with existing CD and DVD reading and

writing architectures.

Their approach is spectral coding, in which each submicron-size

data site on the disk contains many single-bit holograms, all

written in the same volume and each written by a different

wavelength. The researchers have developed and fabricated a

diffractive/refractive lens with a measured depth of focus of

30 µm to write 0.5 µm spots in many colors, and a “wavelength

combiner” that takes white light and creates dozens of discrete

lines across the visible spectrum, each potentially capable of

writing a different wavelength.

While the technology is still in an early phase, the researchers

have succeeded in writing spectrally coded data with three lasers

(red, green, and blue). They have also fabricated a wavelength

combiner that spectrally splits white light, spectrally modulates it

with a reflective spatial light modulator, and then recombines the

light, resulting in many discrete lines (see Fig. 10). In one

experiment, six gratings were recorded in one spot. While extending

the number of gratings into the dozens (and creating commercially

viable hardware) will require further development, the payoff could

be quite large.

FIGURE 10. A wavelength combiner creates many

spectrally narrow lines from white light; each line can

potentially write its own channel of data on an optical disk

in the form of a submicron-size grating.

|

1. G. Roelkens et al., Optics Express 14(18) (Sept. 4,

2006).

2. H. Rong at al., Optics Express 14(15) (July 242006).

3. J.B. Pendry et al., Science 312, 5781) (June 23, 2006).

4. D. Schurig et al., Science Express Reports, published

online Oct. 19, 2006 [DOI: 10.1126/science.1133628].

5. A.M. Armani and K.J. Vahala, Optics Letters 31(12)

(June 15, 2006). (D2O in H2O)

6. W. Chi and N. George, J. Opt. Soc. Am. A 23(9)

(September 2006).

7. P. Wu et al., FWI2 session presentation, Frontiers in

Optics 2006, the 90th OSA Annual Meeting, Rochester, NY (Oct.

8-12, 2006). Laser Focus World December,

2006

Author(s) : John

Wallace

|